Tensile Test Methods for Plastics: ASTM D638

Resin materials (plastics) are found in a wide variety of items used on a daily basis. Recently, plastics have started to be used as structural materials in transportation equipment, such as automobiles and aircraft, due to their strength and light-weight nature. In these applications, it is important to understand the mechanical strength properties of these plastics.

ASTM D638 specifies methods for testing the tensile strength of plastics and other resin materials and for calculating their mechanical properties, and outlines accuracy requirements for the test frames and accessories used.

[ Testing Machine Configurator ]

Create your own testing system configuration

and search quickly by international standards.

ASTM D638 differs slightly from its ISO and JIS equivalents, ISO 527 and JIS K 7161. For more information about ISO 527 and JIS K 7161, please click here.

Automatic Extensometer SIE-560

Test force accuracy of ±1%

ASTM D638 requires a test force accuracy that meets ASTM E4 Class 1, accuracy within ±1% of the indicated test force. Shimadzu’s AG-X plus series, AGS-X series, and EZ-X series test frames and load cells all meet the test force accuracy requirements for ASTM D638.

|

|

|

| AG-X plus Series High-Performance Test Frames | AGS-X Series High-Throughput Test Frames | EZ-X Series Compact Test Frames |

Elongation measurements with 10 μm absolute accuracy and ±0.5% relative accuracy

Specimens for ASTM D638 are dumbbell-shaped with either a 25 mm or 50 mm gauge length; a 50 mm gauge length is recommended. Gauge length changes with ASTM E83 Class B-2 accuracy; an absolute accuracy of 10 μm for a 50 mm gauge length and relative accuracy within ±0.5% are required by ASTM D638 for measuring the tensile modulus of elasticity. Also, for elongation beyond the yield point but less than 20%, Class C accuracy is specified; an absolute accuracy of 50 μm for a 50 mm gauge length and relative accuracy within 1%, and ±10% relative accuracy are required for the rest of the test. For ASTM D638 compliant elongation testing, Shimadzu offers SIE-560SA automatic extensometers, TRViewX non-contact digital video extensometers, and SSG-H one-touch, strain gauge extensometers. In particular, the SIE-560SA automatic extensometer can be programmed to attach and detach automatically from the specimen and can be used for either 25 mm or 50 mm gauge length, improving test efficiency and repeatability.

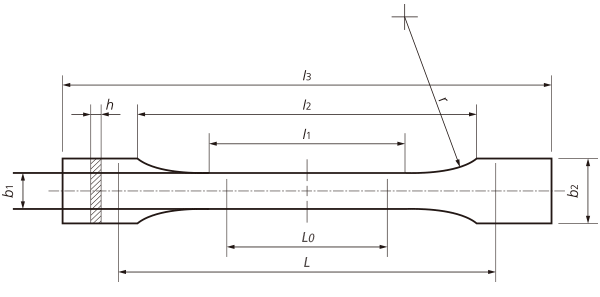

ASTM D638 Specimen Dimensions

| Size | Type I | Type II | Type III | Type IV | Type V |

| Full length,l3 | 165 | 185 | 165 | 115 | |

| Parallel length,l2 | 57 | 57 | 57 | 33 | 63.5 |

| Gauge length,l1 | 50 | 50 | 50 | 25 | - |

| Parallel section width,strong1 | 13 | 6 | 19 | 6 | 7.62 |

| Thickness,h |

7 mm or less ( Recommend 3.2±0.4 mm ) |

7mm to 14mm | 4mm or less | ||

| Grip section width,strong2 | 19 | 19 | 29 | 19 | 9.53 |

| Distance between grips | 115 | 135 | 115 | 65 | 25.4 |

- Five types of specimens

- Type I is recommended

- Type II is used if break does not occur within the parallel section of Type I

- Type V is used for special circumstances, such as testing in a thermostatic chamber

(In addition, other shapes are specified, such as tube and rod shapes.)