Push-Out Test for Pills in Push-Through-Packs

Pharmaceutical and Medical Evaluations

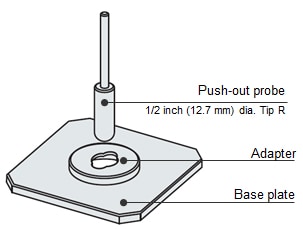

Push-out tests for push-through-packs (PTP) help to evaluate the force applied when a person removes a pill from its wrapping. A pill in a PTP is placed on an adapter, which has a hole in it, and the pill is pushed out from above by a probe. The test force at this point is equivalent to the strength required to push the pill out of the PTP. This strength is evaluated to make it easier to remove pills, while also ensuring they are not inadvertently pushed out of the packaging.

Pill Push-Out Test Using a Pill Push-Out Test Jig Set

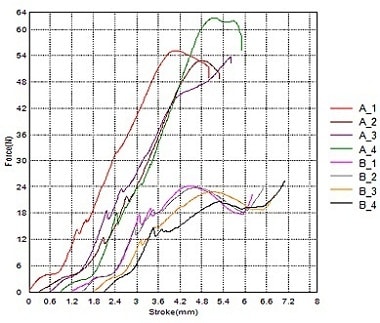

Pill Push-Out Test Results

Tests were performed on two types of PTPs with the same shape (A and B). In comparing the test force when the aluminum wrapping starts to rupture (the point when the test force starts to fall off sharply), it is evident that the values for both types are about the same.

In contrast, they differ significantly in terms of the maximum test force, with the value for A more than twice the value for B. The maximum test force is likely the plastic pressing force required to completely push the pill out of the PTP after the aluminum ruptures.

While PTPs may have the same shape, different kinds of plastic materials are often used for PTP sheets depending on the type of pill. Therefore, experimental evaluations of the ease of pill push-out and retrieval are required depending on the plastic material used and the PTP shape.

Pill Push-Out Test Jig Set

Push-out tests on pills and capsules with different sizes can be performed by changing the adapter. Adapters with four different hole sizes are available, and can be exchanged to suit the pill size. Attach the base plate to the jig platform. When the pill or capsule is pushed out, it is collected by the receptacle provided.

- Light and compact

The compact size fits easily on tables. Testing can be performed in a corner of the office. - A high-precision load cell is adopted. (The high-precision type is class 1; the standard-precision type is class 0.5.)

Accuracy is guaranteed over a wide range, from 1/500 to 1/1 of the load cell capacity. This supports highly reliable test

evaluations. - Jog controller (optional)

This allows hand-held control of the crosshead position. Fine position adjustment is possible using the jog dial. - TRAPEZIUM X Texture operational software

This is the optimal software for a variety of pharmaceutical and cosmetic quality evaluations and physical characteristics measurements, as well as food texture measurements. It can create flexible control patterns and data processing items specific to foods, including hardness, brittleness, and energy. - A wealth of specialized jigs

Supporting the many needs of our customers with special jigs and applications for a number of fields, including foods, pharmaceuticals, electrical machinery & electronics, and plastics.